Project Overview

This project involves the development of a powerful robotic arm that combines precision control with industrial-like strength, and advanced pick-and-place capabilities. Built on a Raspberry Pi platform and PCA9685 servo controller, the arm features a robust mechanical design using aluminum and stainless steel components, paired with high-performance digital servo motors delivering up to 160kg of torque.

The system serves as both a practical automation solution and an educational platform, demonstrating the intersection of mechanical engineering, electronics, and software integration in modern robotics.

Project Budget: €750.

Video Demonstration

Advanced robotic arm in action

Real Life Applications

Diverse applications showing the flexibility of advanced robotics in different fields

PCB Component Placement And Soldering Assistance

Precise PCB component placement and soldering assistance, combining high-torque capability with delicate positioning control for electronics manufacturing.

Project Gallery

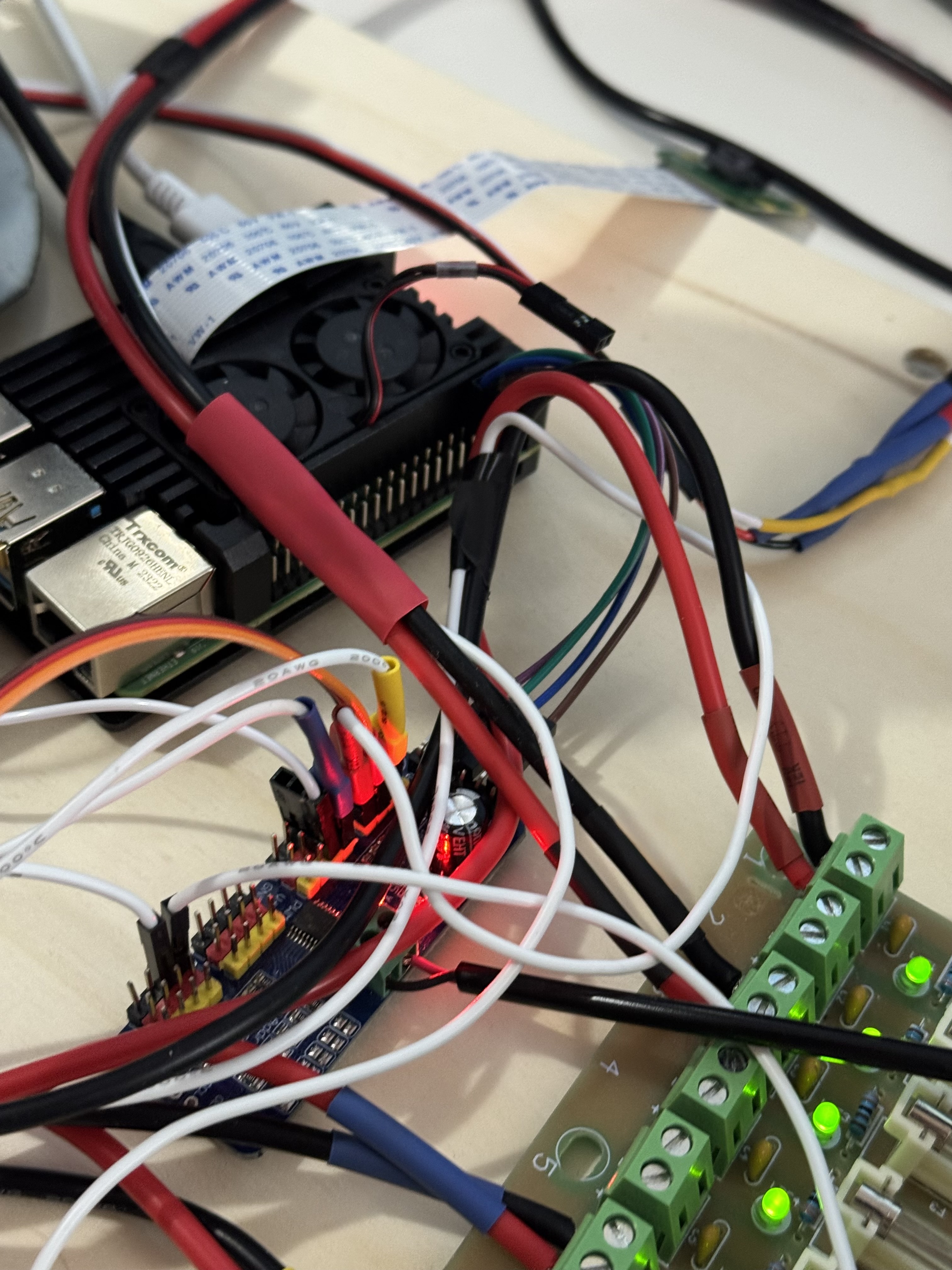

Robotic arm development process and components

Technical Specifications

Detailed breakdown of components and system layout

Hardware Components

- Controller: Raspberry Pi (central processing unit).

- Servo Controller: PCA9685 PWM servo driver board.

- Power Management: Power distribution board.

- Power Supply: High-capacity industrial-grade power supply units.

- Motors: Digital servo motors with variable torque capabilities up to 160kg.

- Construction Materials: Stainless steel for durability and wear resistance, aluminium, and mounting hardware.